KUKA and Jenga

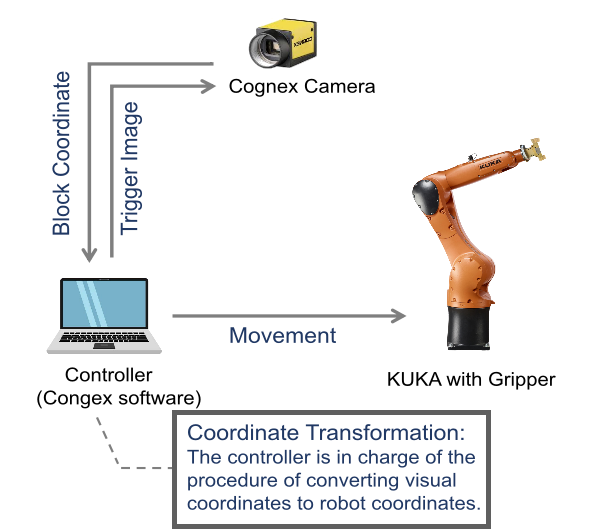

ProjectThe objective of this project is to enable the KUKA robot arm to clamp and place blocks to construct a JENGA Tower. Specifically, the controller retrieves the coordinates of each block from the Cognex Camera and transmits them to the KUKA robot. A critical phase in this process is Coordinate Transformation, where all block coordinates are converted from virtual (pixel-based) coordinates to real-world coordinates before data transmission. Once the KUKA robot receives the world coordinates, it executes a predefined sequence of movements to assemble the JENGA Tower.

Project Tool Details

- Hardware: Cognex Camera, KUKA KR 6 R900 Sixx

- Software: In-Signt Explorer Cognex software, KUKA WorkVisual 8.3

- Tools: FreeCAD, 3D printer

- Programming Languages: KUKA KRL

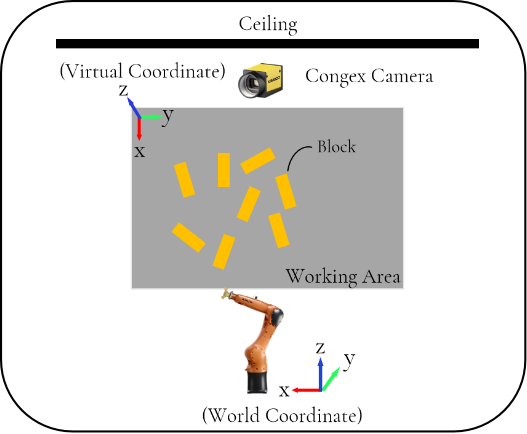

Working Environment Schematic

The brief schematic of the Kuka robot working environment

Structure

The diagram illustrating the interaction between the Cognex camera and the KUKA robot

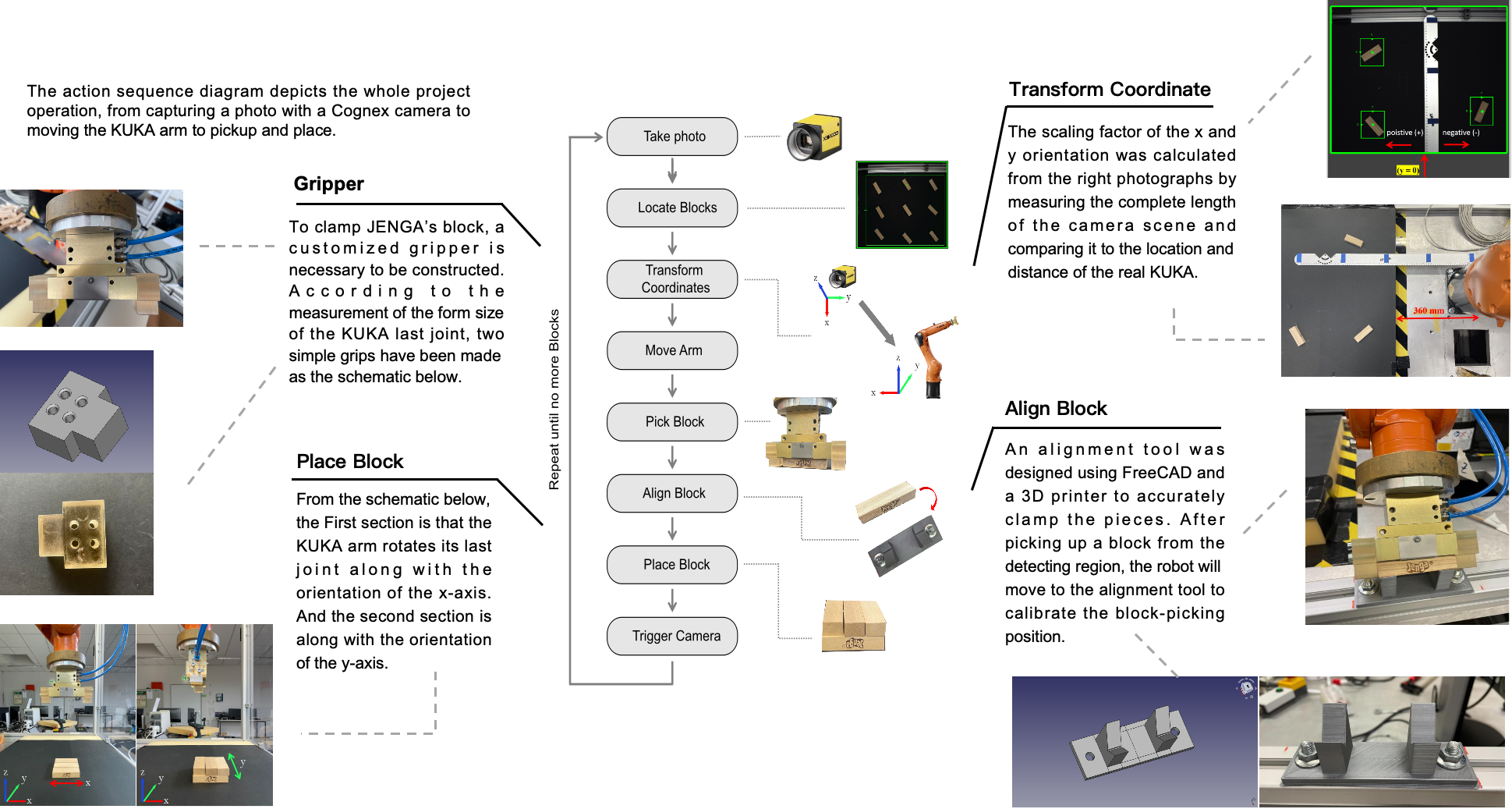

Action Sequence

-

Block Detection via Cognex Camera: The Cognex camera captures an image of the workspace containing the scattered blocks.

-

Image Processing: The camera processes the image to identify the position and orientation of each block in pixel coordinates.

-

Coordinate Transformation: Using a transformation equation, the pixel coordinates of the blocks are converted into world coordinates (X, Y, Z) relative to the KUKA robot’s reference frame.

-

Data Transmission: The world coordinates of the blocks are transmitted to the KUKA robot through a KuKa robot’s internal communication protocol.

-

KUKA Robot Programming: The robot controller receives the block coordinates and uses them in a pre-defined picking sequence programmed in KUKA Robot Language (KRL).

-

Gripper Alignment and Calibration: The calibration model ensures that the gripper aligns accurately to pick up each block, compensating for any errors in the block orientation.

-

Pick-and-Place Operation: The KUKA robot executes the pick-and-place operation, using the provided world coordinates to grip the block and place it in the desired location (e.g., for building a Jenga Tower).